Industrial-Grade Cable Ties: Engineered for Strength, Durability, and Precision

In today’s rapidly evolving industrial landscape, the smallest components can make the biggest difference. Whether you’re managing complex electrical systems in a factory, organizing data cables in a server room, or securing outdoor installations against harsh weather, the reliability of your cable management system is non-negotiable. Enter CHS Industrial-Grade Nylon Cable Ties — engineered not just to hold, but to endure.

For over three decades, CHS has been at the forefront of manufacturing high-performance plastic fasteners. Since 1989, our commitment to innovation, quality control, and material science has made us a trusted name among global manufacturers, engineers, and maintenance professionals. With 36 years of expertise, more than 200 injection molding machines, and a daily production capacity of 50 tons, we don’t just meet industry standards — we redefine them.

Why Choose CHS Cable Ties?

Uncompromising Strength & Load-Bearing Capacity

Forget flimsy ties that snap under pressure. Our industrial-grade nylon cable ties are designed with a reinforced 1mm-thick body and a triple-layer locking mechanism that delivers exceptional tensile strength. Each tie is rigorously tested to withstand loads up to 55kg (121 lbs) — far exceeding standard consumer-grade alternatives.

The secret lies in our proprietary PA6 nylon formulation, which combines high impact resistance with excellent thermal stability. Unlike generic polypropylene ties that become brittle in cold environments or soften under heat, CHS cable ties maintain structural integrity across a wide operating temperature range: from -35°C to +85°C (-31°F to +185°F). This makes them ideal for automotive, aerospace, marine, and heavy machinery applications where performance cannot be compromised.

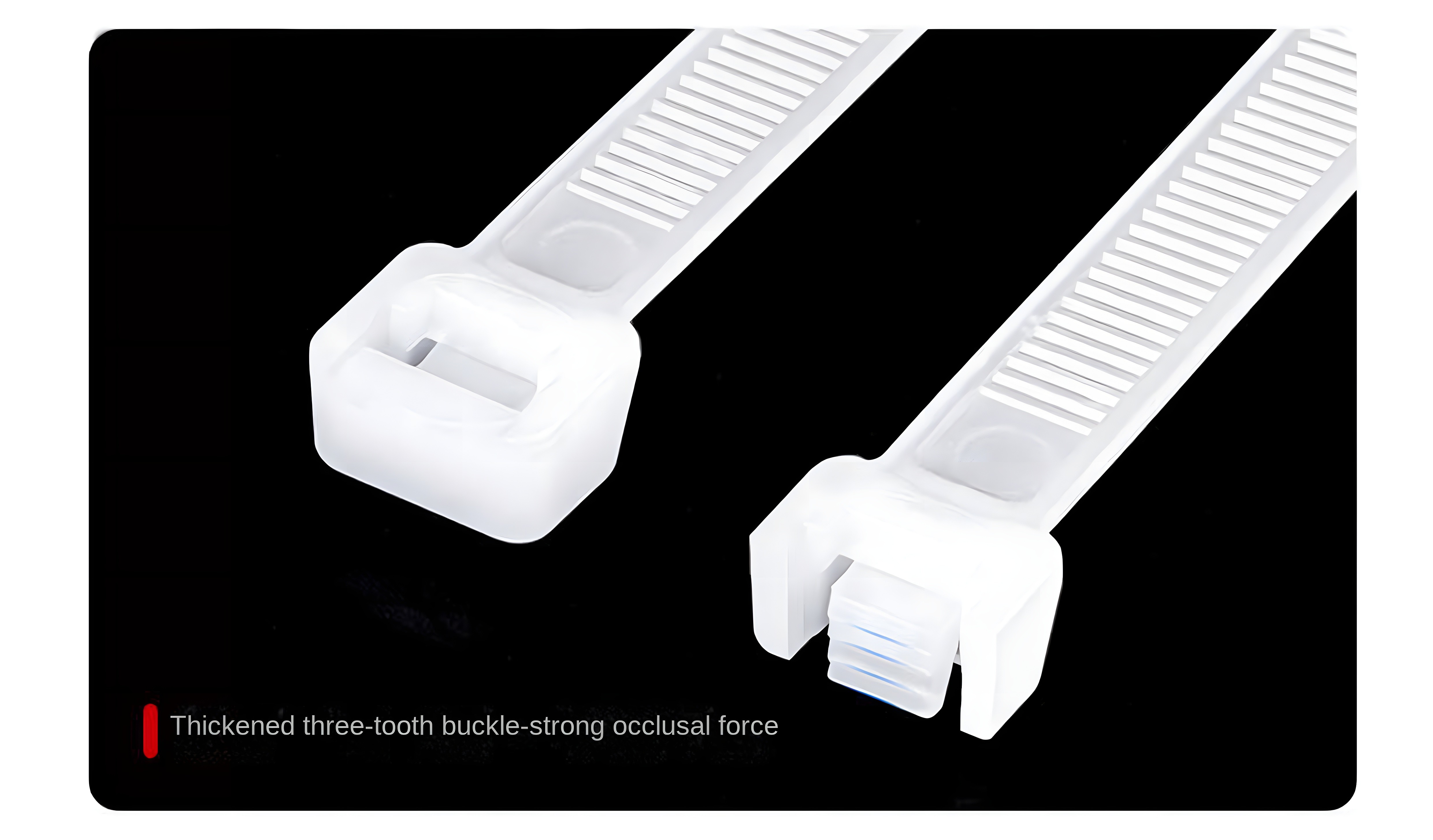

Advanced Locking Mechanism: Secure, Tight, and Tamper-Resistant

Our patented triple-tooth locking head ensures a secure, non-slip grip every time. The interlocking teeth are precision-molded to create maximum surface contact with the tie strap, eliminating slippage even under vibration or dynamic stress. Additionally, the rounded tail end reduces friction during insertion, making installation smoother and faster — whether you’re working with gloved hands or in tight spaces.

What sets our locking mechanism apart is its self-locking design. Once engaged, the tie resists loosening due to thermal expansion, mechanical shock, or UV exposure. This feature is especially critical in outdoor installations, transportation equipment, and industrial automation systems where consistent tension is vital for safety and functionality.

Superior Material Science: Non-Aging, UV-Resistant, and Chemically Stable

We understand that durability isn’t just about physical strength — it’s also about longevity. That’s why we use only premium-grade UV-stabilized PA6 nylon, which resists degradation from sunlight, ozone, and chemical exposure. Unlike cheaper alternatives that yellow, crack, or lose elasticity within months, CHS cable ties retain their color, flexibility, and mechanical properties for years — even in direct sunlight or corrosive environments.

Our materials undergo extensive accelerated aging tests in our UL-Certified In-House Testing Laboratory, ensuring compliance with international standards such as RoHS, REACH, and ISO 9001. Every batch is traceable, and our quality assurance team conducts random sampling to verify tensile strength, elongation at break, and dimensional accuracy — guaranteeing consistency across all production runs.

Precision Engineering for Every Application

Whether you need to bundle thin signal wires or secure thick power cables, CHS offers an extensive range of sizes and configurations to suit every requirement:

- Series 3, 4, 5, 8, 9, 10, and 12 — covering widths from 2.5mm to 10mm and lengths from 100mm to 500mm

- Non-standard and metric versions available for specialized applications

- Black and white color options for visual coding and aesthetic integration

- Multiple packaging quantities (from 100 to 1000 pieces per bag) to match project scale

Each series is meticulously designed to balance flexibility, strength, and ease of use. For example, our Series 5 ties offer optimal thickness for medium-duty bundling, while Series 12 provides heavy-duty reinforcement for large-scale industrial projects. All models feature precise measurement markings along the strap length, allowing technicians to cut ties to exact specifications without guesswork.

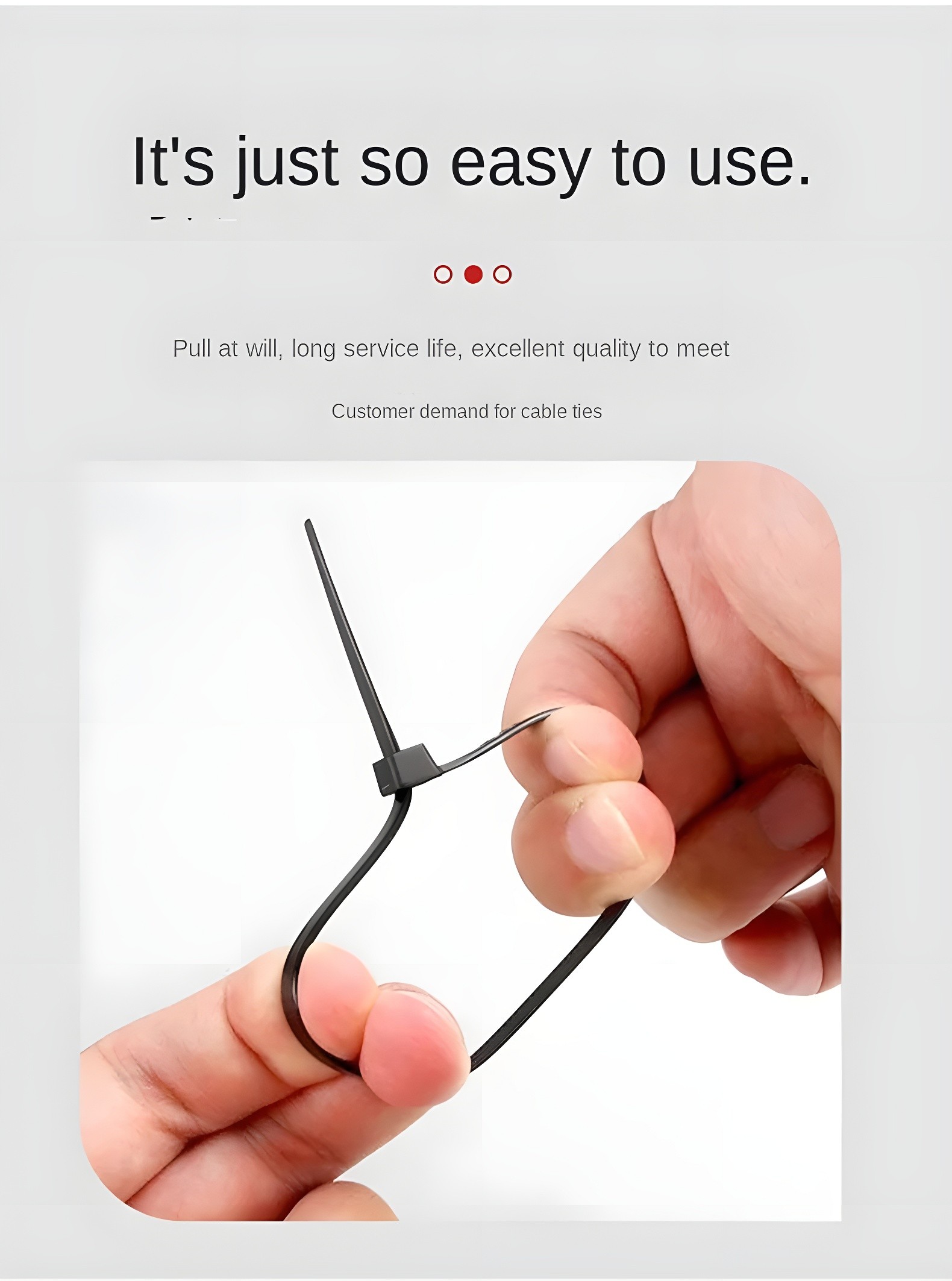

Smart Design Features for Enhanced Usability

Beyond raw performance, CHS cable ties incorporate thoughtful design elements that improve efficiency and reduce waste:

- Ergonomic Head Profile: Rounded edges prevent snagging on clothing or equipment during handling.

- Self-Lubricating Surface: Reduces friction during tightening, minimizing hand fatigue during repetitive installations.

- Cut-Resistant Tail: Reinforced tip prevents accidental cutting during trimming, reducing material waste.

- High-Visibility Markings: Clear embossed text indicates model number, load rating, and compliance certifications for quick identification on-site.

These details may seem minor, but they add up to significant time savings and improved workflow efficiency — especially in high-volume or mission-critical environments.

Certifications That Speak Volumes

Quality isn’t just claimed — it’s certified. CHS holds multiple internationally recognized accreditations that validate our manufacturing excellence:

- SGS Certified – Independent verification of product safety and environmental compliance

- RoHS & REACH Compliant – Free from hazardous substances, safe for electronics and medical applications

- UL Recognized Component – Meets stringent fire safety and electrical insulation standards

- ISO 9001 Quality Management System – Ensures consistent process control and continuous improvement

Our state-of-the-art facility spans over 150,000 square meters and houses more than 1,000 partner units worldwide. We operate one of the largest in-house testing labs in Asia, equipped with advanced machinery for tensile testing, thermal cycling, salt spray corrosion analysis, and UV exposure simulation. This level of investment in R&D and quality assurance translates directly into superior product performance for our customers.

Real-World Applications Across Industries

From automotive assembly lines to offshore wind farms, CHS cable ties are trusted by professionals who demand reliability:

- Automotive Manufacturing: Securing wiring harnesses in engine compartments exposed to extreme temperatures and vibrations

- Data Centers: Organizing fiber optic and Ethernet cables in high-density racks where airflow and accessibility matter

- Renewable Energy: Bundling solar panel arrays and wind turbine cabling subjected to UV radiation and weather extremes

- Marine Engineering: Fastening hydraulic lines and communication cables aboard ships and offshore platforms

- Aerospace: Managing avionics wiring in aircraft where weight, space, and failure tolerance are paramount

Customers consistently report reduced downtime, fewer replacements, and improved maintenance efficiency after switching to CHS cable ties. One major automotive OEM noted a 40% reduction in cable-related service calls following implementation — a testament to the long-term value these seemingly simple components deliver.

Environmental Responsibility Without Compromise

At CHS, sustainability isn’t an afterthought — it’s embedded in our core values. Our production processes prioritize energy efficiency, minimal waste generation, and recyclable materials wherever possible. While our current PA6 formulation is not biodegradable, we are actively researching next-generation bio-based polymers that will offer comparable performance with lower environmental impact.

Moreover, our packaging uses eco-friendly materials and optimized designs to reduce plastic usage. Bulk packs minimize individual wrapping, and we encourage reuse of storage containers wherever feasible. By choosing CHS, you’re not just investing in superior cable management — you’re supporting a company committed to responsible manufacturing practices.

Technical Specifications & Performance Metrics

To give you a clear understanding of what sets CHS apart, here’s a detailed comparison of key performance metrics across our most popular series:

| Series | Width (mm) | Thickness (mm) | Length (mm) | Max Load (kg) | Temp Range (°C) | UV Resistance |

|---|---|---|---|---|---|---|

| 3 | 2.5 | 0.7 | 100–200 | 18 | -35 to +85 | Excellent |

| 4 | 3.0 | 0.8 | 150–300 | 22 | -35 to +85 | Excellent |

| 5 | 4.0 | 0.9 | 200–400 | 30 | -35 to +85 | Excellent |

| 8 | 6.0 | 1.0 | 300–500 | 55 | -35 to +85 | Excellent |

| 9 | 8.0 | 1.2 | 400–500 | 80 | -35 to +85 | Excellent |

| 10 | 10.0 | 1.4 | 500 | 100 | -35 to +85 | Excellent |

All measurements are based on standardized ASTM D638 and ISO 527 tensile testing protocols conducted under controlled laboratory conditions. Actual field performance may vary depending on environmental factors and installation technique.

The Future of Cable Management Starts Here

As industries continue to evolve toward smarter, more connected systems, the role of reliable cable management becomes increasingly critical. From IoT-enabled factories to autonomous vehicles, the infrastructure supporting modern technology depends on components that perform flawlessly — day after day, year after year.

CHS Industrial-Grade Cable Ties represent the culmination of decades of engineering expertise, material innovation, and customer feedback. They are not merely fasteners — they are foundational elements of robust, efficient, and future-ready systems.

When you choose CHS, you’re selecting more than a product. You’re partnering with a manufacturer that understands the real-world challenges faced by engineers, technicians, and operations managers. You’re gaining access to a comprehensive portfolio of solutions backed by rigorous testing, global certifications, and a relentless pursuit of perfection.

In a world where reliability matters most, settle for nothing less than the best. Choose CHS — where strength meets intelligence, and durability meets design.

Note: All technical data provided is based on internal testing and third-party certification reports. Product specifications subject to change without notice. Consult official documentation for latest updates.

More Supplier Information

For detailed supplier information about this product, please visit:

https://www.ericbuy.com/product/detail/taobao/896207492181/detail.html