In today’s competitive global marketplace, the first impression of a product is often its packaging—and nothing elevates that impression quite like professionally sealed, sleek, and protective shrink-wrapped presentation. Introducing our premium-grade PVC heat-shrink film, engineered for precision, durability, and aesthetic excellence. This isn’t just packaging material; it’s a strategic tool for brand enhancement, product integrity, and consumer confidence.

Material Excellence: Why PVC Stands Out

Our heat-shrink film is crafted from high-purity polyvinyl chloride (PVC), a thermoplastic polymer renowned for its exceptional clarity, strength, and dimensional stability. Unlike alternatives such as PET or PE, PVC offers a unique combination of properties that make it ideal for demanding applications across diverse industries:

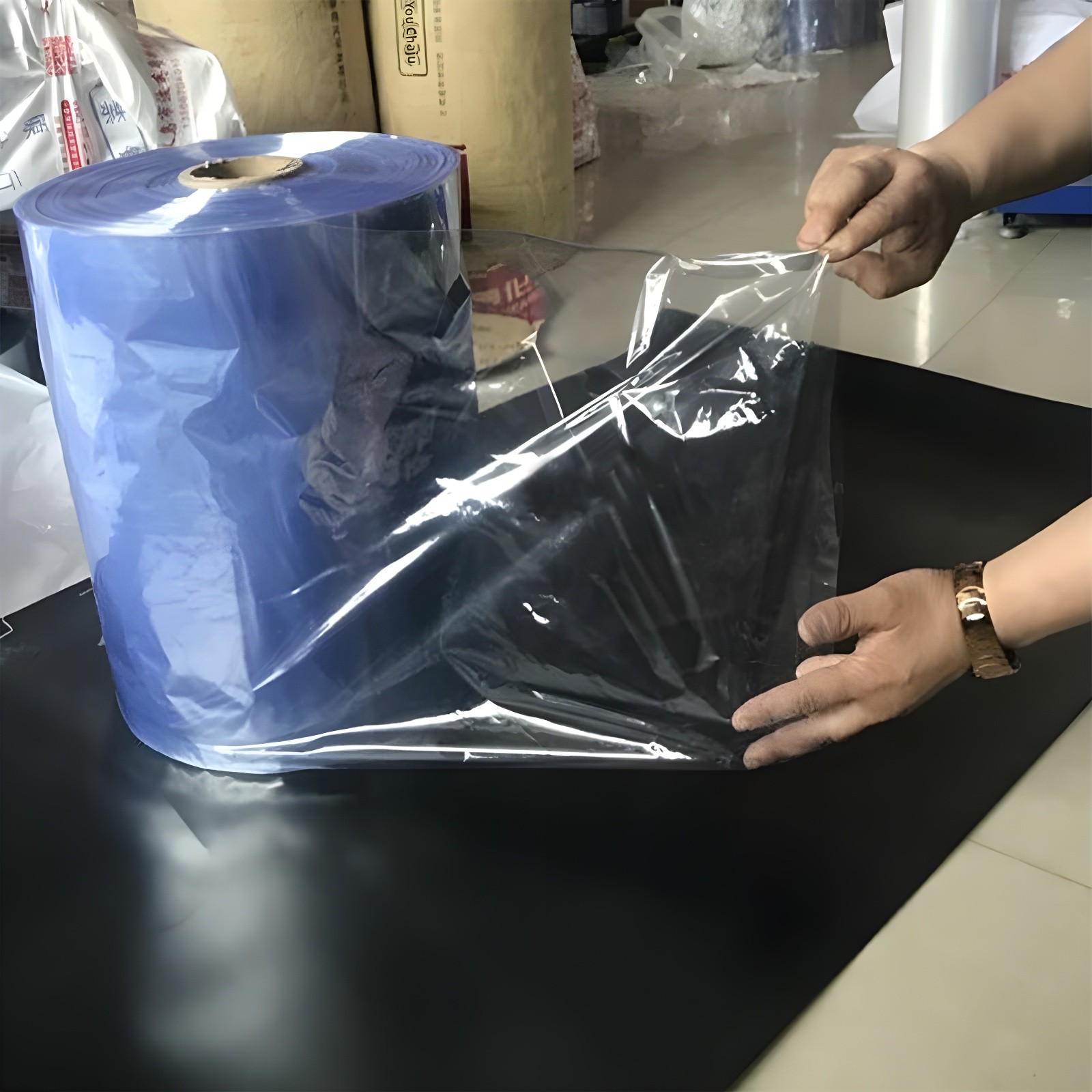

- Optical Clarity: With near-glass transparency, our film allows full visibility of the packaged product—showcasing labels, colors, textures, and design details without distortion or haze. This is critical for retail environments where visual appeal drives purchasing decisions.

- High Shrink Ratio & Uniform Contraction: Engineered to deliver a consistent 45–55% longitudinal and transverse shrink ratio upon heating, the film conforms tightly and evenly around complex geometries—no wrinkles, no looseness, no air pockets. The result is a taut, professional finish that mimics factory-level packaging.

- Tensile Strength & Puncture Resistance: Despite its thin profile (typically ranging from 30μm to 100μm), the film exhibits superior tensile strength (≥35 MPa) and puncture resistance—ensuring products remain securely enclosed during handling, transport, and display. Even sharp edges or irregular contours won’t compromise integrity.

- Chemical Inertness & Food-Safe Compliance: Our PVC formulation is free from phthalate plasticizers (e.g., DEHP, DBP) and meets stringent international standards for indirect food contact (FDA 21 CFR 177.1980, EU Regulation 10/2011). It resists oils, alcohols, mild acids, and common cleaning agents—making it suitable for cosmetics, pharmaceuticals, household goods, and food-related items.

- Thermal Responsiveness: Activated at relatively low temperatures (90–120°C), the film shrinks rapidly and uniformly when exposed to controlled heat sources—such as hot-air guns, tunnel ovens, or even household hairdryers. This ensures energy efficiency and compatibility with both industrial and small-scale operations.

Versatility in Application: From Industrial to Boutique Use

One of the most compelling advantages of our PVC shrink film lies in its extraordinary adaptability. Whether you’re a large-scale manufacturer, a craft producer, or an e-commerce entrepreneur, this material seamlessly integrates into your workflow.

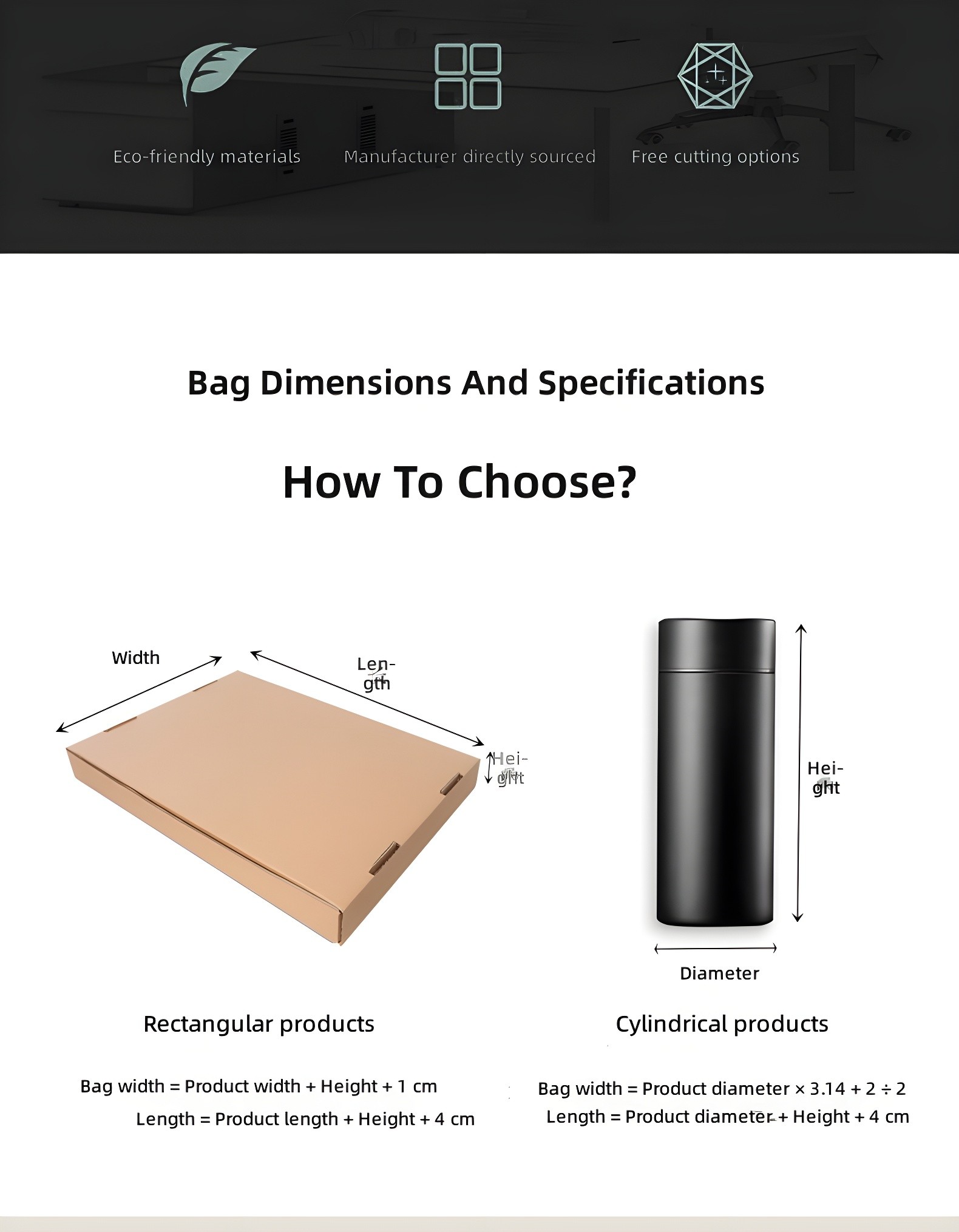

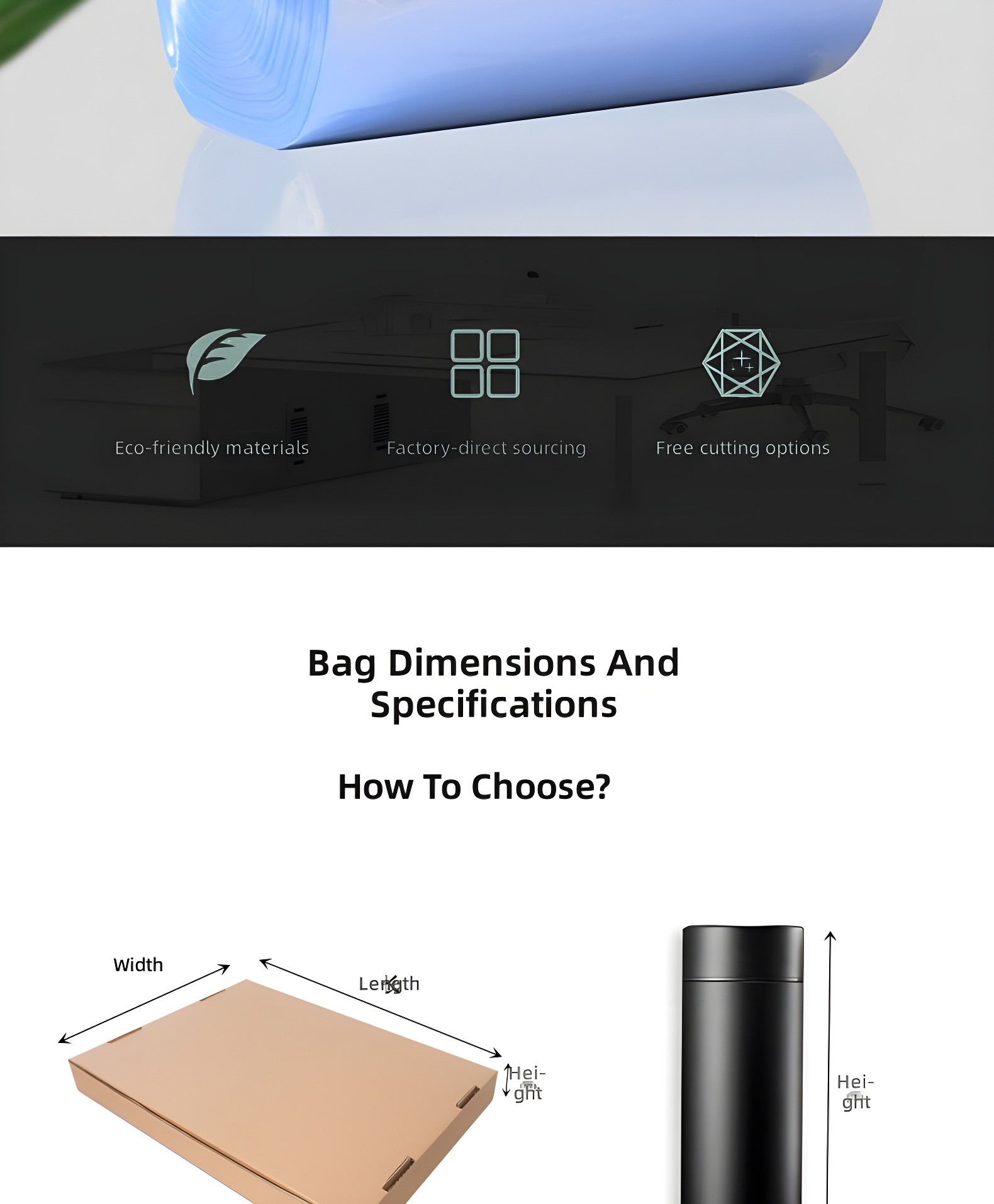

For Long-Form Products

Rectangular or box-shaped items—including electronics, books, stationery, tools, and medical kits—benefit from our flat-sheet roll format. Simply cut to size (with +1 cm allowance per dimension), wrap, and apply heat. The film seals cleanly along edges, creating a rigid, tamper-evident shell that enhances structural support and shelf presence.

For Cylindrical & Irregular Shapes

Bottles, jars, cans, tubes, and spherical objects (e.g., sports balls, decorative ornaments) require precise radial contraction. Our film excels here: when wrapped vertically and heated, it contracts evenly around circumference and height, eliminating sagging or uneven tension. The standard calculation—product height × 1.4 + 2 cm for length, and product diameter × π + 6 cm for width—ensures optimal coverage every time.

Multi-Item Bundling & Display Units

Group packaging? Think gift sets, sample kits, promotional bundles, or retail multipacks. Our film maintains cohesion between disparate items while preserving individual visibility. The tight seal prevents shifting, dust accumulation, and accidental separation—ideal for point-of-sale displays where neatness equals professionalism.

Quality Assurance Through Rigorous Standards

Every roll undergoes a multi-stage quality control protocol before release. We do not merely produce film—we certify performance.

- Thickness Uniformity Testing: Laser micrometers verify ±3% tolerance across the entire roll surface, ensuring consistent shrink behavior and preventing weak spots.

- Shrink Force Measurement: Using ASTM D2732 methodology, we validate that shrink force remains within 150–250 g/mm²—high enough to grip firmly, yet gentle enough to avoid damaging delicate substrates.

- Seal Integrity Verification: Peel tests confirm lap-seal strength exceeds 2.5 N/15mm, guaranteeing durability against environmental stressors like humidity fluctuations or minor impacts.

- UV Stability Assessment: Accelerated aging tests (QUV exposure for 500 hours) demonstrate minimal yellowing or embrittlement—critical for products stored under ambient lighting or in sunlit retail spaces.

This commitment to consistency means your packaging outcome is predictable, repeatable, and scalable—whether you’re producing 10 units or 10,000.

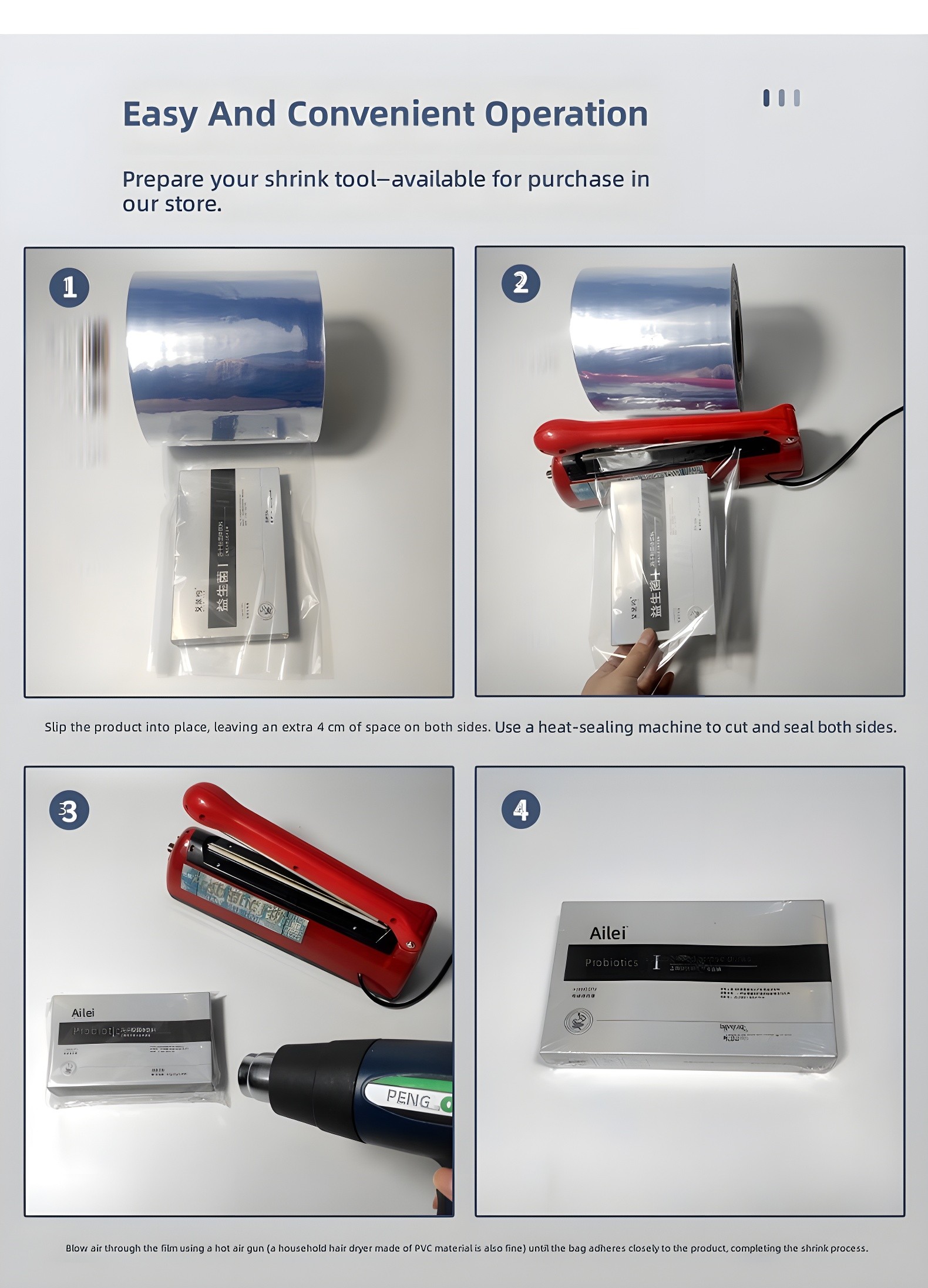

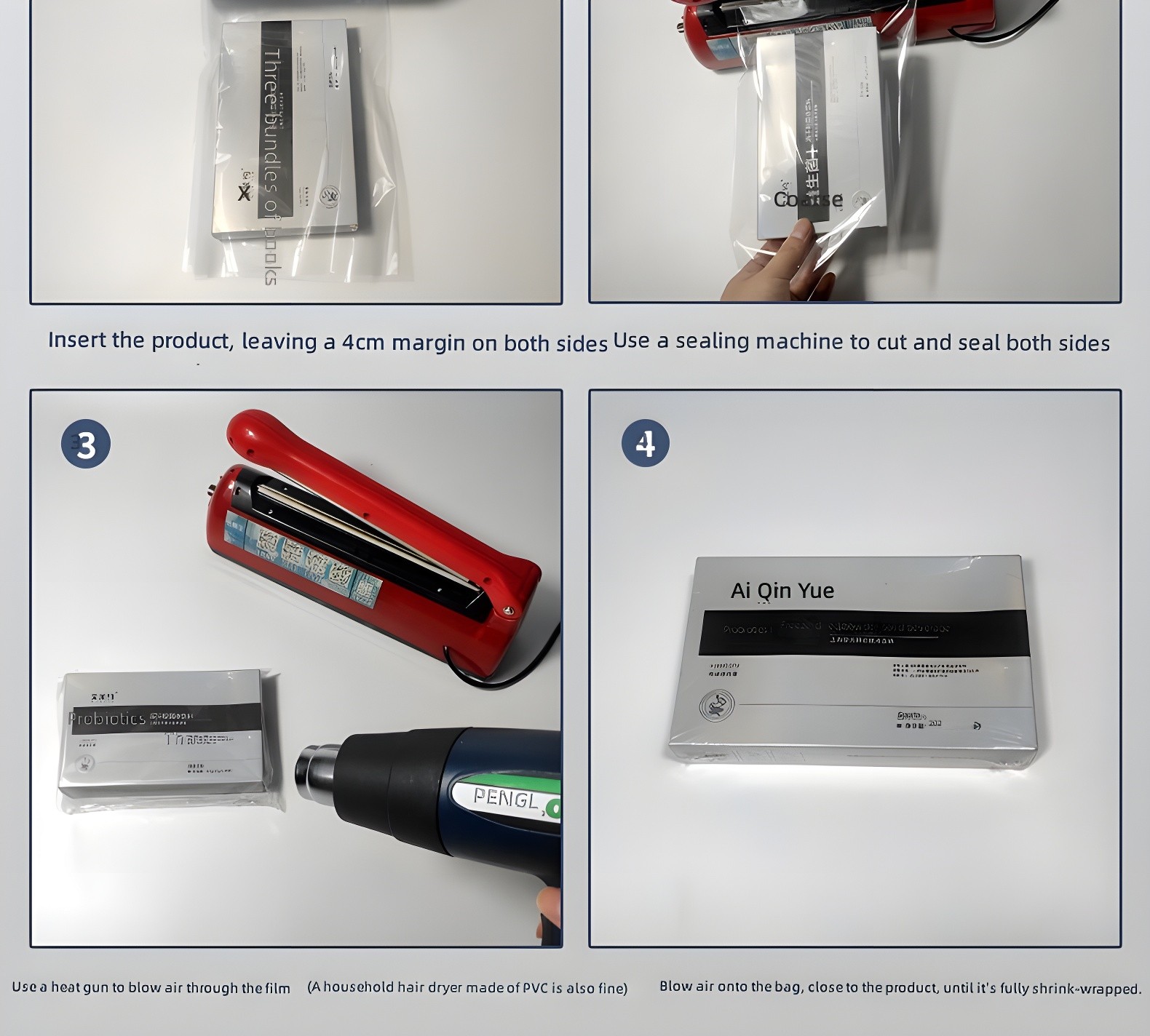

Operational Simplicity: No Specialized Training Required

Packaging should empower—not complicate—your operations. Our system is designed for intuitive execution:

- Preparation: Lay out the film, place the product centrally, and fold edges neatly. Leave approximately 4 cm of excess on both sides for sealing integrity.

- Initial Sealing: Use a standard impulse sealer (or even a hot iron with parchment paper barrier) to create a longitudinal seam. This creates a tube-like enclosure that prevents slippage during heating.

- Heat Activation: Apply warm air (90–120°C) uniformly using a heat gun, moving steadily at 10–15 cm distance. Observe the film “hug” the product within seconds—watch as creases vanish and contours emerge with crisp definition.

- Finishing Touches: Trim excess film if desired, or leave as a clean hem for added rigidity. For premium finishes, consider adding printed labels before shrinking—they’ll adhere flawlessly and resist peeling.

No expensive machinery, no chemical adhesives, no complex calibration. Just reliable results, batch after batch.

Real-World Performance Across Sectors

The proof of value lies in application. Here’s how leading users leverage our PVC shrink film:

- Pharmaceutical & Healthcare: Sealing blister packs, diagnostic kits, and surgical instrument trays. The film’s moisture barrier (WVTR <5 g/m²·24h) protects sensitive components from humidity-induced degradation.

- Cosmetics & Personal Care: Wrapping serums, lotions, and makeup palettes. The glossy finish enhances perceived luxury, while the hermetic seal preserves fragrance integrity and prevents leakage.

- Electronics & Accessories: Securing cables, chargers, earbuds, and small gadgets. Anti-static variants are available upon request to safeguard sensitive circuits during transit.

- Food & Beverage (Non-Direct Contact): Encasing wine bottles, gourmet snacks, tea boxes, and spice jars. The film deters tampering and maintains freshness by blocking airborne contaminants.

- Sports & Leisure Goods: From yoga mats to basketballs, the film provides abrasion resistance and visual cohesion—turning everyday items into premium collectibles.

- Educational & Office Supplies: Binding textbooks, protecting art supplies, or bundling stationery sets. Teachers, retailers, and distributors appreciate the clean, organized appearance it delivers.

Each use case underscores a universal truth: superior packaging doesn’t hide the product—it celebrates it.

Sustainability Meets Functionality

While PVC has faced scrutiny in the past, modern formulations have evolved significantly. Our film is produced using eco-conscious processes:

- Recyclability Infrastructure: In regions with established PVC recycling streams (e.g., Europe’s VinylPlus program), post-consumer film can be reprocessed into new construction profiles, flooring, or cable sheathing—diverting waste from landfills.

- Reduced Material Usage: Thanks to high shrink efficiency, less raw material is needed per unit compared to rigid clamshells or cardboard sleeves—lowering overall carbon footprint.

- Energy-Efficient Processing: Low activation temperatures translate to reduced electricity consumption during shrinking, especially when paired with infrared or convection-based systems.

We recognize that responsible manufacturing is non-negotiable. That’s why we continuously invest in R&D to improve recyclability, reduce additives, and explore bio-based plasticizer alternatives—all without compromising performance.

Technical Specifications at a Glance

| Parameter | Value Range |

|---|---|

| Base Material | Virgin PVC Resin |

| Thickness | 30μm – 100μm (customizable) |

| Width | 100mm – 1200mm (roll) |

| Length | Up to 3000m per roll |

| Shrink Temperature | 90°C – 120°C |

| Shrink Ratio (L/T) | 45% – 55% |

| Tensile Strength (MD/CD) | ≥35 MPa / ≥32 MPa |

| Elongation at Break | ≥200% |

| Water Vapor Transmission Rate | <5 g/m²·24h |

| Oxygen Permeability | <150 cm³·mil/100in²·day |

| Clarity (Haze) | ≤1.5% |

| Gloss (60°) | ≥85 GU |

These figures reflect laboratory-tested averages under standardized conditions. Actual performance may vary slightly based on substrate, ambient humidity, and heating method—but always within commercially acceptable tolerances.

The Future of Packaging Is Transparent, Tight, and Trustworthy

As consumer expectations rise and supply chains grow more intricate, the demand for intelligent, responsive packaging intensifies. Our PVC heat-shrink film answers that call—not with gimmicks, but with engineered reliability. It transforms ordinary products into extraordinary experiences. It safeguards value. It communicates care. It builds trust before the unboxing even begins.

Whether you’re launching a new product line, optimizing existing workflows, or seeking to differentiate in saturated markets, this film delivers measurable ROI through enhanced presentation, reduced damage rates, and elevated brand perception.

Precision-engineered. Field-proven. Universally applicable. This is more than packaging—it’s a statement of professionalism, quality, and attention to detail. And in the world of global commerce, those qualities are priceless.

More Supplier Information

For detailed supplier information about this product, please visit:

https://www.ericbuy.com/product/detail/taobao/879057266368/detail.html