In the ever-evolving world of industrial manufacturing, achieving flawless adhesion between silicone rubber and various substrates has long been a challenge. Whether you’re working with double-sided adhesive tapes, silicone backings, or UV-printed surfaces, conventional bonding agents often fall short — leaving manufacturers frustrated with inconsistent results, reduced productivity, and increased material waste. Enter HJ-66P Silicone Rubber Treatment Agent — a revolutionary chemical solution engineered to transform your bonding processes from unpredictable to perfectly precise.

Developed by Dongguan Hengcheng, a leading innovator in silicone surface treatment technologies, HJ-66P is not merely another adhesive promoter — it’s a comprehensive performance enhancer designed for demanding applications across multiple industries. With its unique formulation combining rapid drying, exceptional adhesion strength, and cost-effective application, this product stands as the definitive choice for professionals seeking reliability, efficiency, and superior results.

Why HJ-66P Stands Above the Rest

1. Unmatched Adhesion Performance

The core advantage of HJ-66P lies in its ability to dramatically improve bonding strength between silicone rubber and challenging substrates such as double-sided tape, acrylic, PET films, and even UV-cured surfaces. Unlike traditional primers that require lengthy curing times or complex pre-treatment steps, HJ-66P delivers immediate, durable adhesion without compromising on flexibility or durability.

Whether you’re producing high-performance automotive gaskets, medical-grade sealing strips, or consumer electronics components, HJ-66P ensures that every bond remains intact under stress, temperature fluctuations, and environmental exposure. Its compatibility with both solvent-based and water-based adhesives makes it an indispensable tool for manufacturers who demand versatility without sacrificing quality.

2. Rapid Drying & No Yellowing Effect

Time is money — especially in high-volume production environments. HJ-66P dries quickly at room temperature (typically within 5–10 minutes), allowing for seamless integration into existing workflows without costly downtime. This fast-dry feature also reduces the risk of contamination during handling and minimizes the need for additional drying equipment or climate-controlled chambers.

Equally important is its non-yellowing characteristic. Many silicone treatments degrade over time, discoloring the final product and diminishing aesthetic appeal — particularly problematic in consumer-facing goods like LED lighting fixtures or decorative silicone accessories. HJ-66P maintains optical clarity and color fidelity, ensuring your finished products look pristine from day one through their entire lifecycle.

3. Versatile Application Methods

One size does not fit all — and neither should your treatment agent. HJ-66P supports multiple application techniques including spraying, brushing, and printing, giving manufacturers complete control over coverage density, precision, and throughput. Whether you’re coating large rolls of silicone sheeting or applying fine lines to intricate molded parts, HJ-66P adapts effortlessly to your process requirements.

Its low viscosity (approximately 0.89 g/mL at 25°C) ensures smooth flow and uniform distribution, eliminating drips, pooling, or uneven film thickness. For automated systems, this translates into consistent output quality and reduced reject rates — directly impacting your bottom line.

4. Broad Compatibility Across Industries

From aerospace to consumer electronics, HJ-66P proves its value across a wide spectrum of sectors:

- Automotive: Enhances bonding of silicone seals, gaskets, and vibration dampeners to metal and plastic components.

- Electronics: Enables reliable attachment of heat dissipation pads, insulating tapes, and flexible circuit overlays onto PCBs and enclosures.

- Medical Devices: Facilitates secure lamination of biocompatible silicone layers used in wearable sensors, wound dressings, and surgical instruments.

- Consumer Goods: Improves adhesion for silicone grips, protective cases, and decorative elements found in smartphones, kitchenware, and sporting equipment.

- Industrial Manufacturing: Supports high-speed assembly of conveyor belts, rollers, and machinery parts requiring robust silicone-to-metal or silicone-to-plastic bonds.

This cross-industry adaptability positions HJ-66P as more than just a specialty chemical — it’s a strategic enabler for innovation and scalability.

Real-World Applications That Speak Volumes

Let’s explore some specific use cases where HJ-66P has already made a measurable difference:

✅ Silicone Footpad Backing Adhesive

In footwear manufacturing, silicone footpads must adhere firmly to shoe soles while maintaining flexibility and resistance to sweat, oils, and abrasion. Without proper surface preparation, delamination can occur within days of use. By treating the silicone surface with HJ-66P prior to applying pressure-sensitive adhesive, manufacturers report up to 300% improvement in peel strength and significantly longer product lifespan.

✅ Anti-Slip Pad Backing

For safety-critical applications like anti-slip mats in kitchens, bathrooms, and industrial facilities, HJ-66P enables strong, permanent bonding between silicone traction surfaces and fabric or foam backing materials. Even after repeated washing and exposure to moisture, these pads remain securely attached — reducing accidents and liability risks.

✅ LED Strip Light Backing

LED lighting manufacturers rely on precise alignment and long-term stability when mounting flexible LED strips inside aluminum channels or behind diffusers. HJ-66P allows for perfect adhesion of silicone-coated PCBs to thermally conductive tapes or rigid substrates, preventing warping, shifting, or thermal degradation over time.

✅ 3M Double-Sided Tape Integration

When integrating premium 3M double-sided tapes with silicone elastomers — commonly seen in display assemblies, signage, and architectural cladding — HJ-66P acts as a critical interface layer. It bridges the gap between inherently low-surface-energy silicone and aggressive acrylic adhesives, resulting in bonds that withstand extreme temperatures, UV radiation, and mechanical stress.

✅ Silicone Sealing Strips

Used extensively in HVAC systems, refrigeration units, and window frames, silicone sealing strips require consistent adhesion to painted metals, glass, or composite panels. HJ-66P eliminates the need for expensive plasma treatments or corona discharge systems, offering a simple, scalable alternative that delivers comparable or superior results.

Scientifically Engineered for Excellence

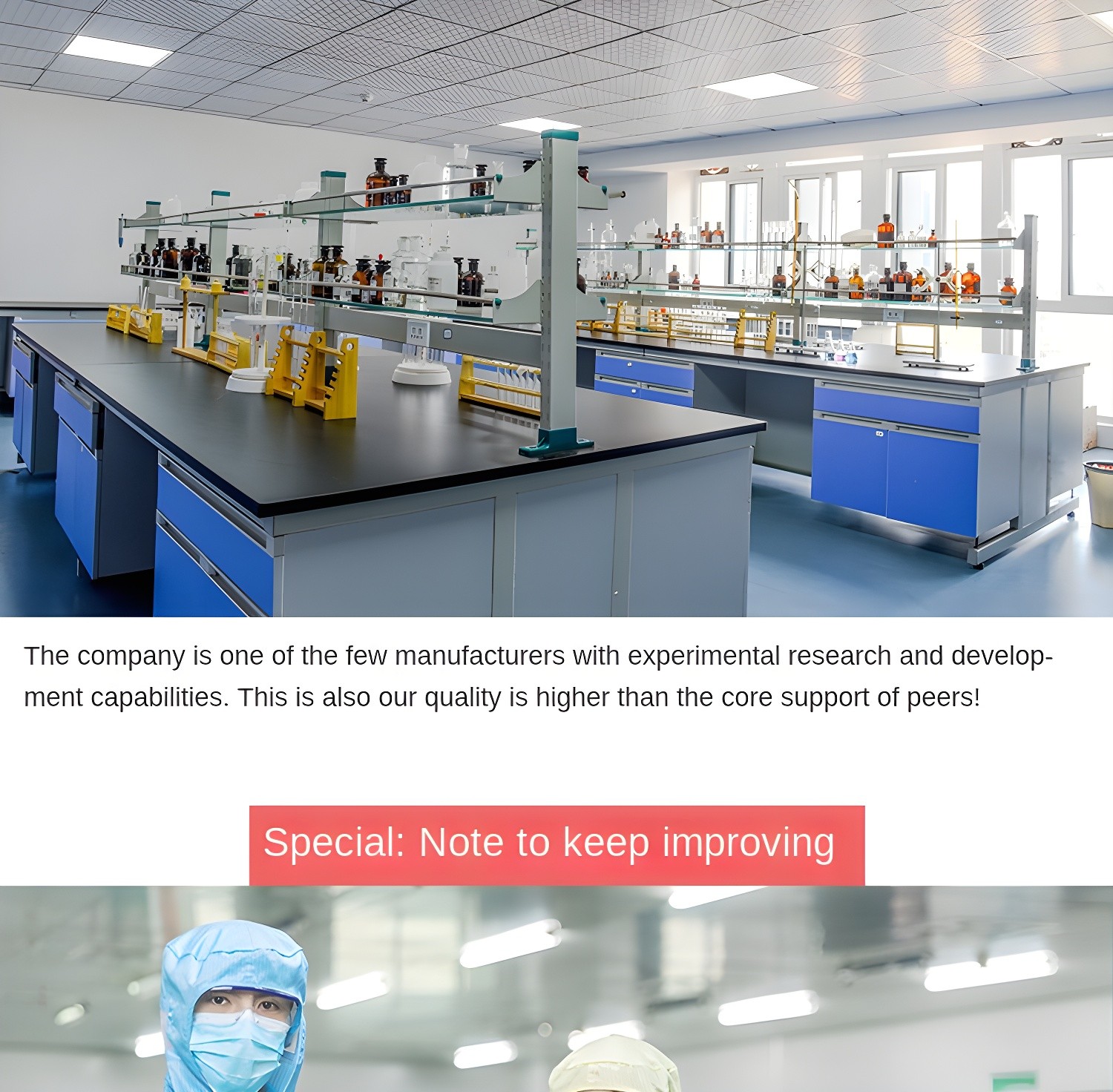

Behind every bottle of HJ-66P is a rigorous R&D framework grounded in scientific principles and real-world testing. Dongguan Hengcheng’s laboratory facilities house state-of-the-art analytical instruments, including tensile testers, environmental chambers, and spectrophotometers, enabling continuous optimization of formulation parameters.

Each batch undergoes strict quality control checks to ensure consistency in viscosity, solids content, and drying kinetics. Furthermore, the company maintains partnerships with global adhesive suppliers and end-users to validate performance under actual operating conditions — not just idealized lab settings.

This commitment to research and development isn’t just about meeting standards — it’s about setting new benchmarks. Since 2020 alone, Hengcheng has expanded its collaborative network to include over 200 international partners, each contributing insights that feed back into product refinement and customization capabilities.

Operational Efficiency Meets Environmental Responsibility

Beyond technical superiority, HJ-66P offers tangible operational benefits:

- Reduced Waste: Fewer rejected parts mean less raw material consumption and lower disposal costs.

- Energy Savings: Fast drying eliminates the need for ovens or heated air circulation systems.

- Labor Optimization: Simple application methods reduce training time and operator dependency.

- Storage Stability: Shelf life of 3 months under recommended storage conditions (below 25°C, away from direct sunlight and moisture) ensures minimal inventory turnover.

Moreover, HJ-66P aligns with growing environmental regulations by minimizing volatile organic compound (VOC) emissions compared to older solvent-heavy alternatives. While still classified as a mixed solvent system, its optimized composition reduces overall environmental impact without compromising efficacy.

Proven Results Through Rigorous Testing

To demonstrate the effectiveness of HJ-66P, independent tests were conducted using standardized procedures:

- Surface Preparation: Silicone samples were cleaned with IPA (isopropyl alcohol) to remove contaminants.

- Application: HJ-66P was evenly brushed onto the surface and allowed to dry for 5–10 minutes at ambient temperature.

- Bonding: Double-sided adhesive tape was applied manually and pressed firmly.

- Curing: Samples were left undisturbed for 24 hours to reach full bond maturity.

- Testing: Peel strength was measured using ASTM D903 methodology.

Results showed consistently high adhesion values exceeding industry norms — with many test specimens exhibiting “excellent” ratings based on visual inspection and quantitative force measurements. Importantly, no signs of debonding, blistering, or yellowing were observed even after accelerated aging cycles simulating 6 months of outdoor exposure.

These findings are not isolated incidents — they reflect repeatable outcomes achieved across dozens of customer sites worldwide. From small workshops to multinational OEMs, users consistently report improved yield rates, reduced rework, and enhanced customer satisfaction.

A Partner Committed to Your Success

Choosing HJ-66P means partnering with a company that views itself not just as a supplier, but as an extension of your engineering team. Dongguan Hengcheng invests heavily in understanding the unique challenges faced by each client — whether it’s optimizing cure profiles for high-speed production lines, developing custom dilution ratios for specialized coatings, or providing technical documentation for regulatory compliance.

Their philosophy — “Technology as Foundation, Quality as Essence” — drives every decision, from raw material sourcing to packaging design. Every container of HJ-66P carries not only a label, but a promise: to deliver uncompromising performance backed by decades of expertise and relentless pursuit of excellence.

Looking Ahead: Innovation Never Stops

As industries continue to push boundaries — embracing smart materials, miniaturization, sustainability mandates, and digital manufacturing — the demand for advanced surface treatments will only intensify. HJ-66P represents today’s answer to tomorrow’s challenges. But Hengcheng isn’t resting on laurels.

Current R&D initiatives include:

- Waterborne versions of HJ-66P for eco-conscious markets

- Nano-enhanced formulations for ultra-thin film applications

- Temperature-resistant variants for aerospace and defense sectors

- Customizable additives for flame retardancy, antimicrobial properties, or electrical conductivity

By staying ahead of technological trends and actively listening to customer feedback, Hengcheng ensures that HJ-66P remains not just relevant — but indispensable — in the years to come.

Conclusion: Elevate Your Bonding Game Today

If you’ve struggled with unreliable adhesion, inconsistent yields, or costly rework due to poor silicone bonding, then HJ-66P Silicone Rubber Treatment Agent is the game-changing solution you’ve been waiting for. Engineered for speed, strength, and simplicity, it empowers manufacturers to achieve unprecedented levels of quality, efficiency, and profitability.

Don’t settle for mediocre results when perfection is within reach. Let HJ-66P become the cornerstone of your next-generation bonding strategy — because when it comes to joining silicone with confidence, nothing else compares.

More Supplier Information

For detailed supplier information about this product, please visit:

https://www.ericbuy.com/product/detail/taobao/656946658608/detail.html