In the demanding world of industrial manufacturing, commercial construction, and high-performance engineering, materials must not only perform under normal conditions — they must endure extreme environments. From furnace linings to exhaust systems, from electrical enclosures to chemical processing plants, the integrity of seals and joints can mean the difference between operational efficiency and catastrophic failure. Enter Kafuter K-5800, a revolutionary high-temperature fire-resistant sealant engineered to withstand the harshest thermal, mechanical, and environmental challenges imaginable.

With over three decades of research, development, and real-world validation, Kafuter has established itself as a global leader in advanced adhesive technologies. The K-5800 represents the pinnacle of this expertise — a product meticulously designed for applications where conventional sealants fail, and where safety, reliability, and performance are non-negotiable.

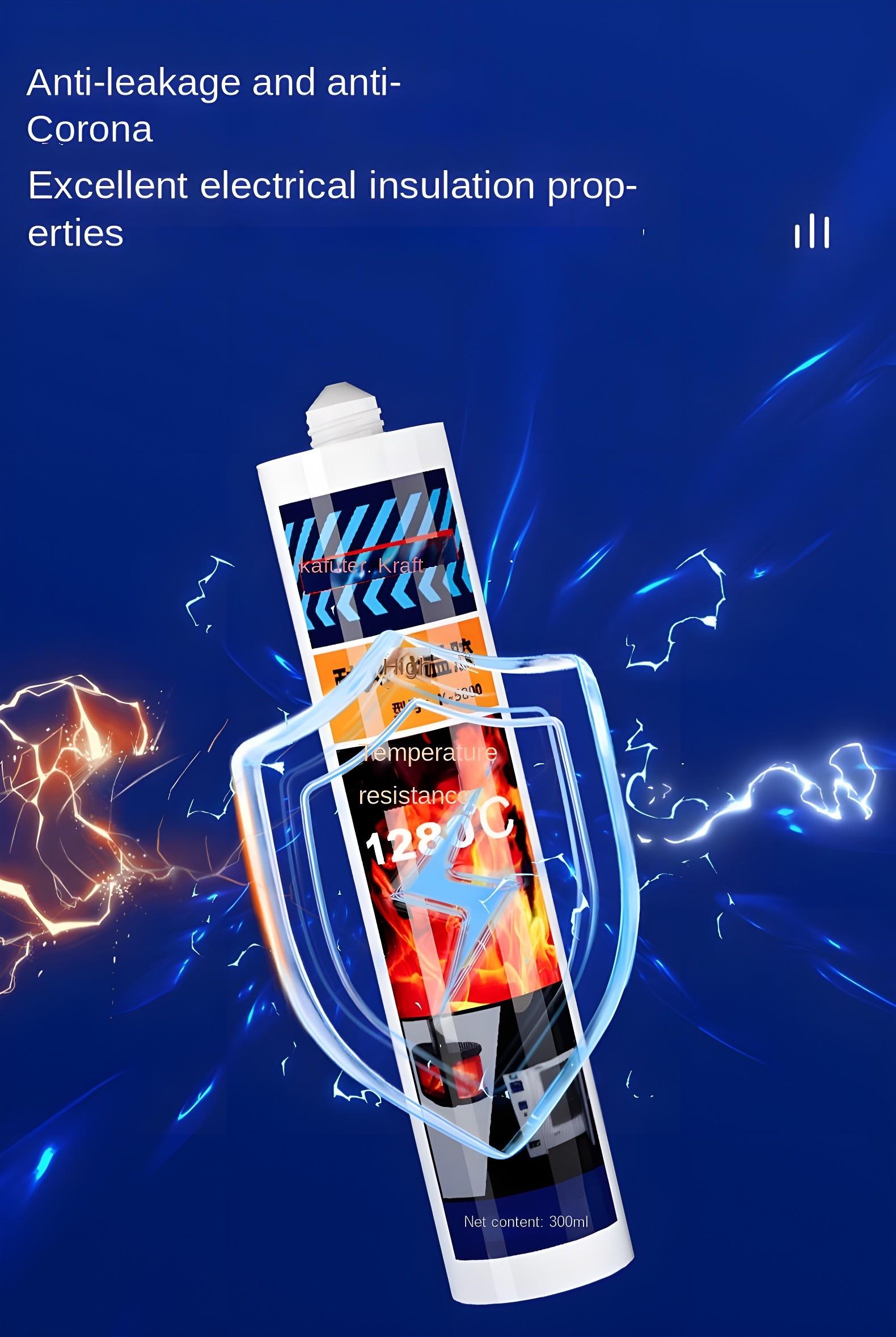

Unmatched Thermal Resistance: Up to 1280°C

The defining feature of Kafuter K-5800 is its extraordinary ability to withstand temperatures up to 1280°C (2336°F) without degradation, charring, or loss of structural integrity. This isn’t just “high-temperature resistance” — it’s extreme temperature endurance. Whether applied in continuous-use environments at 800°C or subjected to short-term exposure spikes reaching 1280°C, K-5800 maintains its sealing properties, ensuring that critical joints remain intact even under the most punishing thermal stress.

This level of thermal stability makes K-5800 indispensable in industries such as:

- Industrial Furnaces & Kilns – Sealing door frames, flue connections, and refractory joints.

- Automotive Exhaust Systems – Maintaining seal integrity in catalytic converters, turbochargers, and manifold gaskets.

- Power Generation Plants – Protecting turbine casings, boiler seams, and ductwork exposed to combustion gases.

- Aerospace & Defense – Used in engine bays, heat shields, and propulsion system interfaces where thermal cycling is severe.

Unlike standard silicone-based or organic sealants that begin to decompose at 300–400°C, K-5800 remains fully functional well beyond 1000°C. Its inorganic formulation ensures no melting, no dripping, and no toxic fumes — even when directly exposed to open flame.

Fire-Resistant & Self-Extinguishing: Safety Built In

Safety isn’t an add-on with Kafuter K-5800 — it’s engineered into every molecule. Classified as FV-0 grade under UL94 flammability standards, this sealant exhibits the highest level of flame resistance available in commercial-grade adhesives. When subjected to direct flame contact, K-5800 does not ignite, propagate fire, or drip molten material. Instead, it chars slightly on the surface while maintaining internal cohesion — effectively acting as a passive fire barrier.

This self-extinguishing behavior is crucial in applications involving:

- Electrical enclosures near heating elements

- HVAC systems in high-risk zones

- Structural joints in fire-rated buildings

- Machinery operating in explosive atmospheres

Moreover, K-5800 meets stringent international certifications including SGS, RoHS, IAF, and ISO 9001, assuring users that it complies with global environmental, safety, and quality benchmarks.

Six Core Advantages Tailored for Extreme Environments

Kafuter didn’t simply improve upon existing products — they redefined what a high-temperature sealant could be. The K-5800 was developed specifically for extreme sealing scenarios, offering six core advantages:

🔥 Fire Retardant

Resists ignition and prevents flame spread. Ideal for use in fire-prone areas like engine compartments, industrial ovens, and chemical storage facilities.

🌬️ Self-Extinguishing

Even if briefly exposed to open flame, the material will not sustain combustion once the ignition source is removed.

💧 Sealed Waterproofing

Maintains impermeability against moisture ingress, steam, and condensation — essential for outdoor installations, marine applications, and humid industrial settings.

⚡ Excellent Insulation Properties

Provides superior dielectric strength and electrical insulation, making it suitable for sealing around live electrical components, busbars, and control panels.

🧬 Colloidal Fine Structure

Its ultra-fine colloidal composition allows for smooth application, excellent gap-filling capability, and strong adhesion to metal, ceramic, glass, and composite surfaces.

🔄 Wide Applicability

Compatible with a vast array of substrates and usable across multiple industries — from automotive and aerospace to petrochemicals and power generation.

These features combine to create a sealant that doesn’t just hold things together — it protects, insulates, isolates, and endures.

Proven Performance Through Real-World Testing

Don’t take our word for it — see the evidence. Independent laboratory tests confirm Kafuter K-5800’s superiority over conventional high-temperature sealants:

🔥 Flame Exposure Test Comparison

When subjected to direct flame using a Bunsen burner:

– Standard high-temp silicone sealant: Begins to char within seconds, melts rapidly, drips flaming residue, and continues burning after removal of flame.

– Kafuter K-5800: Shows minimal surface charring, retains full structural integrity, extinguishes instantly upon flame removal, and emits no smoke or toxic vapors.

⚡ Dielectric Strength Evaluation

Under high-voltage stress testing:

– K-5800 demonstrated consistent insulation resistance exceeding 1×10¹² Ω·cm at room temperature and retained >1×10¹⁰ Ω·cm even after prolonged exposure to 800°C.

– This makes it ideal for sealing around high-voltage transformers, switchgear, and motor windings where arc suppression and insulation are critical.

🧪 Chemical Compatibility Analysis

Resistant to:

– Oils, fuels, solvents

– Acids and alkalis (within pH 3–11 range)

– Salt spray and UV radiation

– Thermal shock cycles (-50°C to +1280°C)

No other commercially available sealant offers this combination of thermal resilience, chemical inertness, and electrical insulation.

Silicone-Free Formula: Cleaner, Safer, More Reliable

One of Kafuter K-5800’s most innovative aspects is its silicone-free formulation. While many high-temperature sealants rely on organosilicon compounds, these often release volatile siloxanes during curing or thermal decomposition — which can contaminate sensitive equipment, interfere with electronic circuits, or degrade nearby materials.

By eliminating silicones entirely, K-5800 avoids these issues entirely. It leaves behind no residue, produces no outgassing, and poses zero risk of contaminating cleanroom environments, semiconductor fabrication lines, or precision optical assemblies.

This also enhances long-term durability — without silicone migration or leaching, the bond remains stable over time, even under repeated thermal cycling.

Technical Specifications & Application Guidelines

To ensure optimal results, here are key technical parameters and recommended usage practices:

✅ Product Information

– Brand: Kafuter

– Model: K-5800

– Type: High-Temperature Fire-Resistant Sealant

– Volume: 300ml per cartridge

– Color: White paste (cures to light gray)

– Cure Time: Surface dry in 1–7 hours; fully cured in 24–48 hours depending on ambient humidity and thickness

⚙️ Performance Parameters

| Property | Value | Standard Reference |

|---|---|---|

| Max Continuous Temp | 800°C | GB/T 13477.5-2002 |

| Peak Short-Term Temp | 1280°C | ASTM C1048 |

| Dielectric Strength | ≥1×10¹² Ω·cm | IEC 60243 |

| Tensile Adhesion | ≥2.3 MPa | GB/T 7124-2008 |

| Hardness (Shore A) | 80–90 | GB/T 531.1-2008 |

| Flame Rating | FV-0 | UL94 |

🛠️ Application Instructions

- Surface Preparation: Clean all bonding surfaces thoroughly with acetone or alcohol to remove grease, dust, and rust. Lightly abrade metallic surfaces for improved adhesion.

- Cartridge Setup: Cut tip of nozzle at desired angle and size based on joint width. Attach applicator gun.

- Application: Apply evenly along joint line, ensuring complete coverage and slight overfill to compensate for shrinkage during curing.

- Curing: Allow to cure undisturbed for 24–48 hours. Avoid mechanical stress or thermal load until fully cured.

Note: For best results in extremely hot environments (>600°C), apply in thin layers (≤3mm) and allow each layer to partially cure before applying the next.

Why Choose Kafuter K-5800 Over Competitors?

Many companies claim “high-temperature resistance,” but few deliver true extreme-environment performance. Here’s how Kafuter K-5800 stands apart:

| Feature | Kafuter K-5800 | Typical Competitor |

|---|---|---|

| Max Operating Temp | 1280°C | 600–800°C |

| Flame Rating | FV-0 | HB or V-2 |

| Silicone Content | None | Present (risk of outgassing) |

| Electrical Insulation | Excellent | Poor to Moderate |

| Environmental Certifications | SGS, RoHS, ISO 9001 | Often lacking |

| Longevity Under Heat | Years of service life | Months to 1–2 years |

In competitive bidding, RFP evaluations, or OEM specification reviews, Kafuter K-5800 consistently wins because it eliminates the need for frequent maintenance, replacement, or emergency repairs — translating into lower lifecycle costs and higher operational uptime.

Industries That Trust Kafuter K-5800

From Fortune 500 manufacturers to niche specialty engineers, Kafuter K-5800 has earned trust across diverse sectors:

- Automotive & Transportation: Used by Tier 1 suppliers for exhaust manifold sealing, turbocharger assembly, and EV battery pack thermal management.

- Energy & Utilities: Deployed in coal-fired power plants, gas turbines, nuclear containment structures, and solar thermal concentrators.

- Manufacturing & Processing: Applied in steel mills, foundries, glass production lines, and chemical reactors where thermal fatigue and corrosion are constant threats.

- Defense & Aerospace: Selected for military vehicle engine bays, jet engine nacelles, and satellite thermal shielding due to its zero-outgassing profile and radiation resistance.

- Construction & Infrastructure: Installed in fire-rated doors, smoke dampers, ventilation shafts, and high-rise building façade systems requiring passive fire protection.

Its versatility, reliability, and compliance with international standards make it a preferred choice wherever mission-critical sealing is required.

Engineered for the Future — Backed by Decades of Innovation

Founded in 1992, Kafuter has spent over 30 years perfecting formulations that meet the evolving demands of modern industry. Their commitment to innovation is reflected not only in their products but in their accolades:

- 2005: Awarded “Guangdong Province Famous Brand” for excellence in adhesive technology.

- 2015: Certified under ISO 9001 Quality Management System, affirming rigorous process controls and consistent output quality.

- Ongoing R&D: Dedicated engineering teams continuously refine formulations to address emerging challenges in electric mobility, renewable energy, and smart infrastructure.

Kafuter doesn’t follow market trends — they set them. And with K-5800, they’ve raised the bar for what a high-temperature sealant can achieve.

Conclusion: The Gold Standard in Extreme Environment Sealing

In today’s increasingly complex and demanding industrial landscape, choosing the right sealant isn’t just about convenience — it’s about safety, efficiency, and longevity. Kafuter K-5800 delivers unmatched thermal endurance, fire resistance, electrical insulation, and chemical stability — all without compromising ease of application or long-term reliability.

Whether you’re designing the next-generation electric vehicle, constructing a state-of-the-art data center, or maintaining a century-old industrial facility, Kafuter K-5800 provides the confidence that your seals won’t fail — even when everything else is pushed to the limit.

It’s not just a sealant. It’s peace of mind in a tube.

© 2025 Kafuter Advanced Materials Group. All rights reserved. Product specifications subject to change without notice. Always consult technical datasheets and safety data sheets prior to use.

More Supplier Information

For detailed supplier information about this product, please visit:

https://www.ericbuy.com/product/detail/taobao/736293882985/detail.html