In today’s fast-paced manufacturing and consumer electronics environments, the demand for reliable, high-performance adhesives has never been greater. Whether you’re assembling intricate electronic components, bonding durable materials in automotive interiors, or repairing household appliances, having an adhesive that delivers instant strength, long-term durability, and environmental safety is not just a convenience — it’s a necessity.

Introducing JULI JL-330 High-Concentration Fast-Drying Adhesive — a revolutionary bonding solution engineered for professionals and DIY enthusiasts alike. With over 28 years of industry expertise, JULI has perfected this formula to meet the most demanding standards across hundreds of industries. This isn’t just glue; it’s precision engineering in a bottle.

Unmatched Performance: Why JULI JL-330 Stands Above the Rest

1. Exceptional Bonding Strength Across Diverse Materials

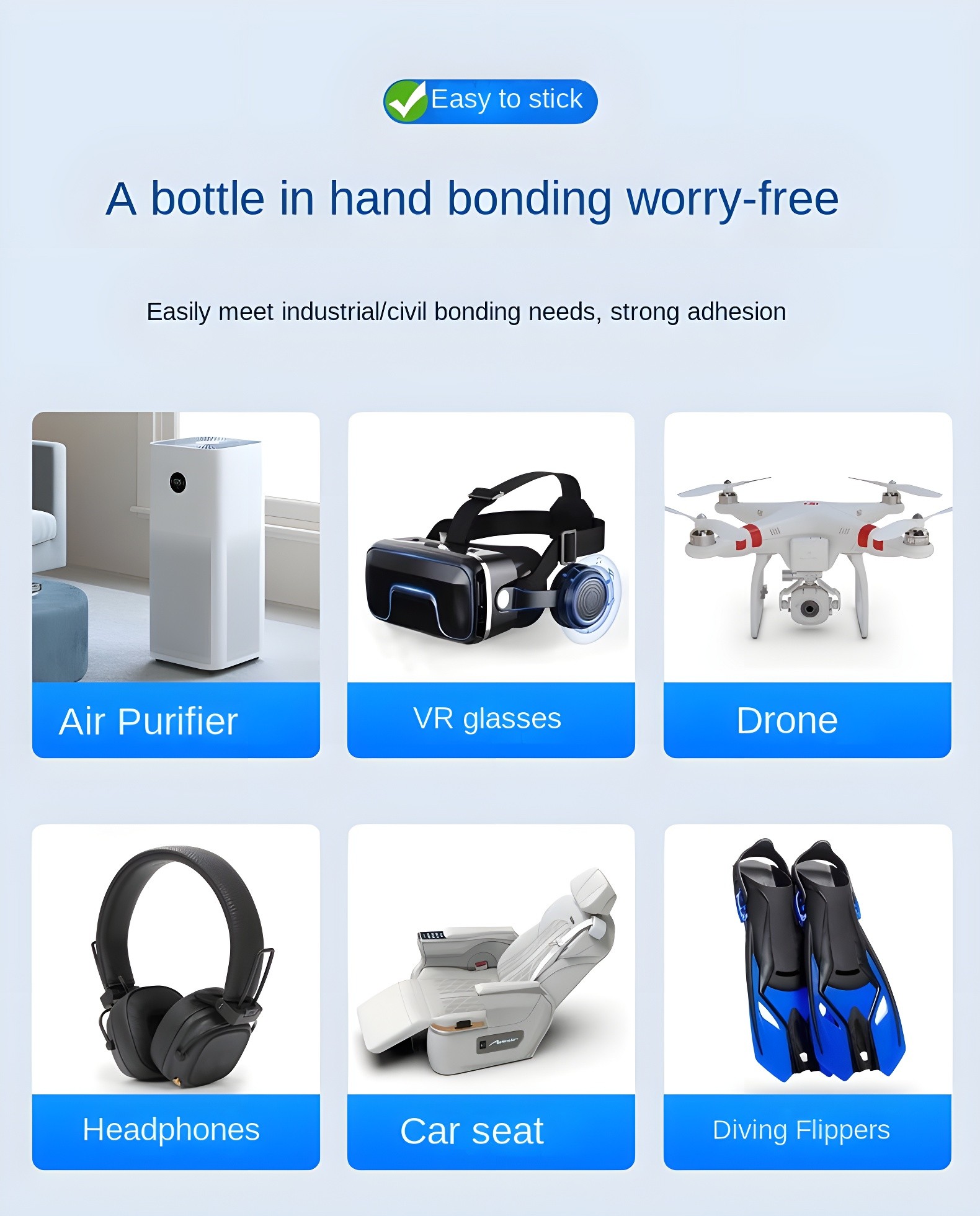

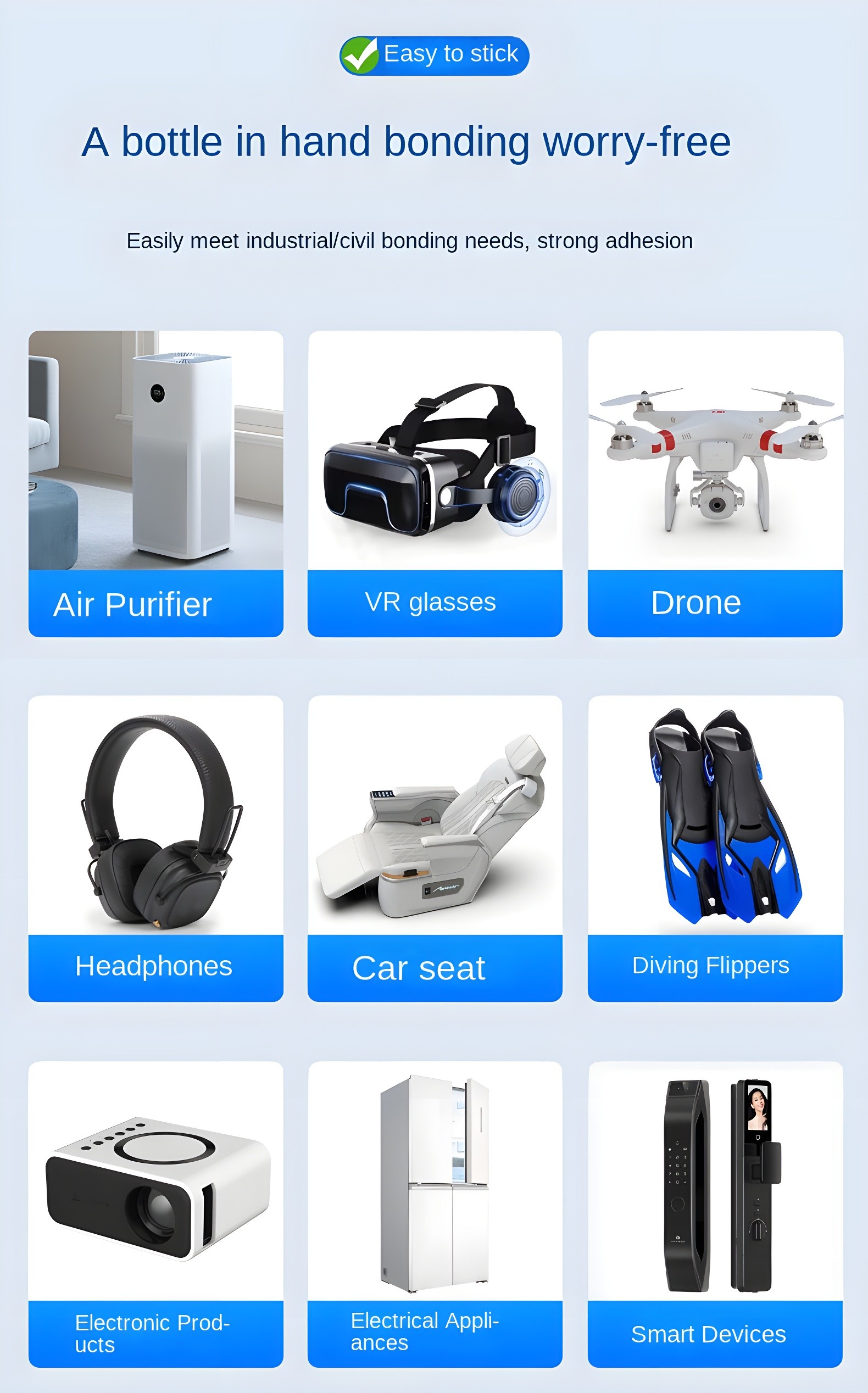

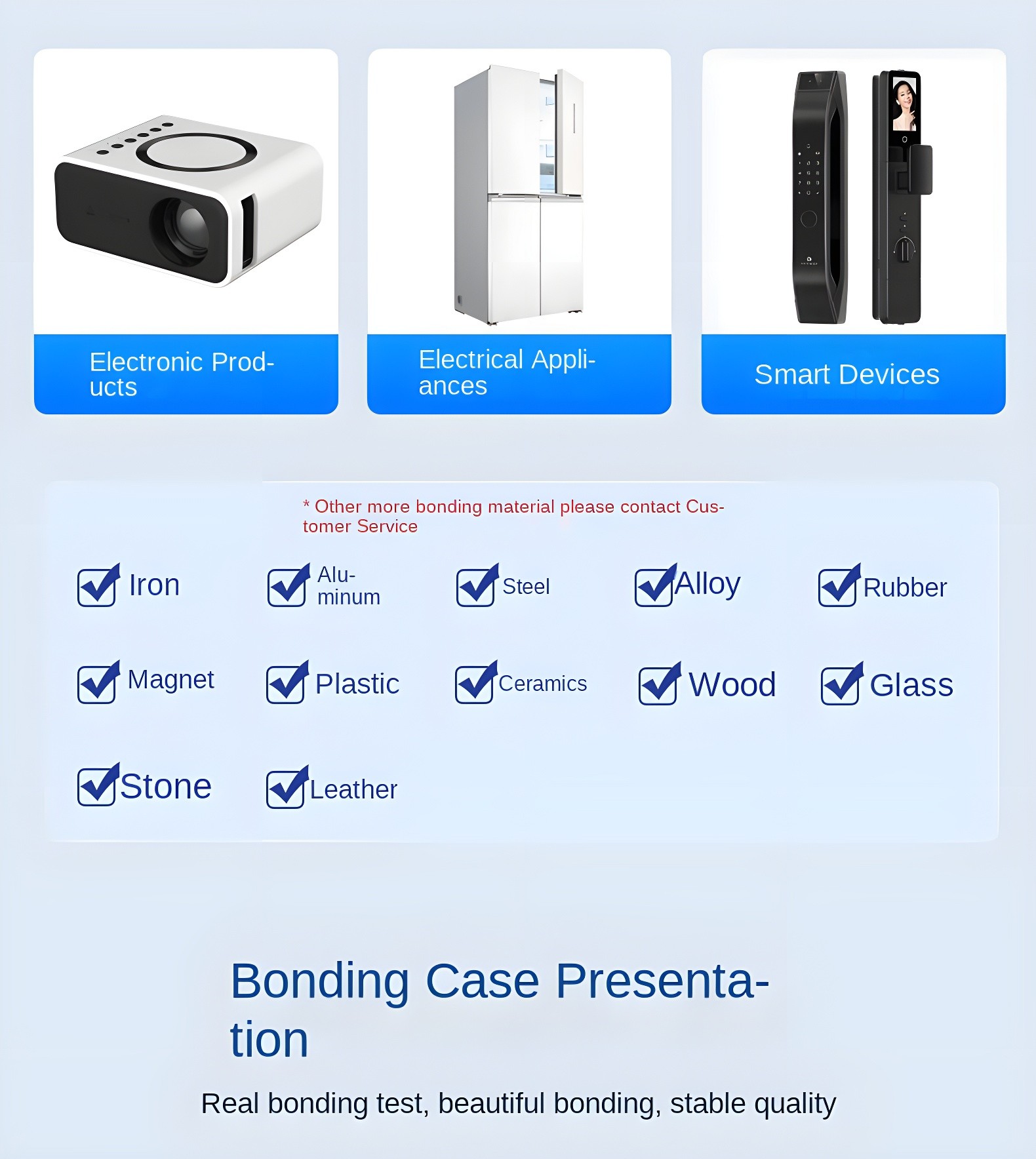

JULI JL-330 is not limited to one type of surface. It excels at bonding an extraordinary range of materials including:

- Metals: Iron, aluminum, steel, alloys

- Plastics & Polymers: ABS, PVC, PP, PE, TPU, EVA, PPS

- Rubber & Elastomers: Silicone, TPR, EPDM

- Ceramics & Glass

- Wood & Stone

- Leather & Fabric

Whether you’re repairing a cracked smartphone case, securing a loose car seatbelt buckle, or bonding metal brackets on industrial machinery, JL-330 ensures a permanent, resilient bond that withstands vibration, temperature fluctuations, and daily wear and tear.

The adhesive’s molecular structure allows it to penetrate micro-pores and create a mechanical interlock with surfaces, resulting in bonds that are often stronger than the materials themselves.

2. Lightning-Fast Curing Without Compromising Flexibility

One of the standout features of JULI JL-330 is its rapid curing time. Within 10–20 seconds, the adhesive begins to set, allowing for immediate handling and assembly. Full cure is achieved within minutes, drastically reducing production downtime and accelerating project completion.

But speed doesn’t mean brittleness. Unlike many fast-cure cyanoacrylates that become rigid and prone to cracking under stress, JL-330 retains excellent flexibility even after curing. This makes it ideal for applications where parts experience thermal expansion, impact, or constant movement — such as drone frames, VR headsets, or automotive interior trim.

3. Low White-Out Effect for Professional Aesthetics

A common complaint with many super glues is the unsightly white residue (known as “blooming”) that appears around the bond line, especially when exposed to moisture or humidity. JULI JL-330 is specially formulated to minimize this effect, ensuring clean, invisible bonds that maintain the original appearance of your product.

This feature is particularly valuable in consumer electronics, where aesthetics matter just as much as functionality. Imagine bonding a transparent phone case without leaving any visible marks — that’s the level of precision JL-330 delivers.

4. Environmental Safety and Compliance

In an era where sustainability and regulatory compliance are paramount, JULI JL-330 stands out as an eco-conscious choice. It is certified under multiple international environmental and safety standards, including:

- SGS

- RoHS (Restriction of Hazardous Substances)

- MSDS (Material Safety Data Sheet)

- VOC (Volatile Organic Compound) compliant

- REACH (Registration, Evaluation, Authorisation and Restriction of Chemicals)

Additionally, it carries certifications from PICC (People’s Insurance Company of China) for product liability insurance, giving manufacturers peace of mind knowing their products are backed by rigorous quality assurance.

The adhesive is also non-toxic, low odor, and safe for use in enclosed spaces — making it suitable for both factory floors and home workshops.

Proven Reliability Through Real-World Applications

JULI doesn’t just make claims — it proves them through real-world usage across thousands of industries. Here are some compelling examples:

Consumer Electronics & Gadgets

From bonding headphone housings to securing camera modules inside smartphones, JL-330 provides the precision and reliability needed for miniaturized, high-tech devices. Its low viscosity allows for precise application even in tight spaces, while its quick cure ensures efficient mass production.

Automotive Interiors

Car seats, dashboard panels, trim pieces, and even airbag components require adhesives that can withstand extreme temperatures and constant vibration. JL-330 has been tested and proven effective in automotive OEM environments, offering a bond that lasts the lifetime of the vehicle.

Home Appliances & Smart Devices

Refrigerator door seals, washing machine control panels, robotic vacuum cleaner casings — all benefit from JL-330’s ability to bond dissimilar materials while resisting moisture, heat, and chemicals.

Industrial Manufacturing

From robotics arms to conveyor belt components, JL-330 performs reliably in heavy-duty industrial settings. Its resistance to oils, solvents, and UV exposure makes it ideal for outdoor equipment and machinery operating in harsh conditions.

Engineered for Precision: Technical Specifications

| Feature | Specification |

|---|---|

| Brand | JULI |

| Model | JL-330 |

| Color | Transparent |

| Volume | 25ml |

| Shelf Life | 6 months (unopened) |

| Working Temperature Range | -50°C to +120°C |

| Curing Time | 10–20 seconds |

| Storage Conditions | Store in a cool, dry place away from direct sunlight |

| Key Properties | High bonding strength, low white-out, flexible, shock-resistant, chemical-resistant |

The 25ml bottle is designed for controlled dispensing, minimizing waste and maximizing efficiency. The fine-tipped nozzle allows for pinpoint accuracy, essential for delicate electronics or intricate assemblies.

Quality You Can Trust: Backed by Decades of Expertise

JULI isn’t a newcomer to the adhesive industry — it’s a veteran. With over 28 years of dedicated R&D and manufacturing experience, the company has developed more than 600 specialized formulations tailored to specific material combinations and environmental conditions.

Their commitment to quality is reflected in their certifications:

- ISO 9001: Quality Management System

- ISO 14001: Environmental Management System

- ISO 45001: Occupational Health and Safety Management

These aren’t just badges on a website — they represent a culture of continuous improvement, rigorous testing, and unwavering customer focus.

Moreover, JULI operates its own research labs and production facilities, ensuring complete control over every stage of development and manufacturing. This vertical integration guarantees consistency, traceability, and the highest possible standards of purity and performance.

Why Professionals Choose JULI JL-330

For Engineers & Designers

You need an adhesive that won’t fail under stress. JL-330 offers predictable, repeatable performance across millions of applications. Its compatibility with automated dispensing systems makes it ideal for high-volume production lines.

For Maintenance Technicians

When downtime costs money, you need a repair solution that works immediately. JL-330 lets you fix broken parts on the spot — no waiting, no clamping, no mess.

For Hobbyists & DIY Enthusiasts

Whether you’re building a custom drone, restoring vintage furniture, or crafting prototypes, JL-330 gives you professional-grade results without the professional price tag. Its ease of use and forgiving nature make it perfect for beginners and experts alike.

Safety First: Responsible Use Guidelines

While JULI JL-330 is safe for general use, responsible handling is always recommended:

- Keep away from children and pets.

- Use in well-ventilated areas.

- Avoid contact with eyes and skin. In case of accidental contact, rinse thoroughly with water and seek medical attention if irritation persists.

- Do not expose to open flames or direct sunlight.

- Store in a cool, dry place between 5°C and 27°C.

The product complies with all relevant safety regulations and includes clear warning symbols on packaging to ensure user awareness.

Conclusion: The Benchmark for Modern Adhesives

In a market flooded with generic super glues and unreliable knock-offs, JULI JL-330 emerges as the definitive choice for anyone who values performance, reliability, and innovation. It’s not just about sticking things together — it’s about creating lasting connections that endure the test of time, environment, and use.

Whether you’re working on cutting-edge technology, maintaining critical infrastructure, or simply fixing something around the house, JULI JL-330 empowers you to achieve results that exceed expectations.

Its combination of high concentration, fast drying, flexible bonding, low white-out, and environmental compliance sets a new standard for what an industrial-strength adhesive should be.

With decades of proven success, thousands of satisfied customers, and a relentless commitment to quality, JULI continues to lead the way in adhesive technology. And with JL-330, you’re not just choosing a product — you’re investing in confidence, precision, and excellence.

Note: All data presented herein is based on internal testing and field reports. Actual performance may vary depending on substrate preparation, environmental conditions, and application technique. Always conduct preliminary tests before full-scale implementation.

More Supplier Information

For detailed supplier information about this product, please visit:

https://www.ericbuy.com/product/detail/taobao/965475859265/detail.html